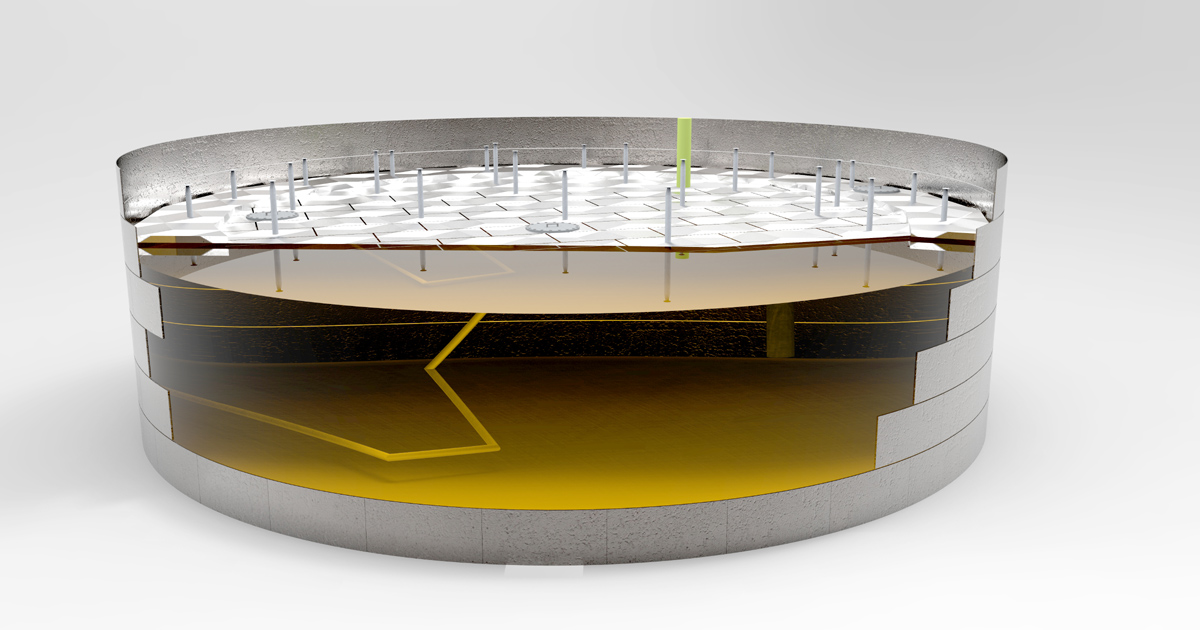

External floating roof seals

External Floating Roof is used in the tank which is not fixed on the tank, this roof goes up and down according to the travel of product surface, also works as weather shield being exposed to ambient circumstance. This is why it needs thick deck and secondary seal made by steel material. Various type of peripheral seal applied to prevent evaporation, design for high-efficiency and durability of sealing.

Design features

- API650 Appendix C

- Chemical Resistence

- Tank Shell Condition

- US EPA requirement

- FEM for Structural Analysis

- Accessories by customer requirement

Key Benefts

Designed to accommodate roof movement, shell variation, contraction, and expansion.

Designed to accommodate roof movement, shell variation, contraction, and expansion.- being used throughout the range of crudes and refined products.

- The seal can be mounted either in contact with the liquid or vapor tight

-being used on rim gaps varying in size from 100mm to 250mm to cope with tank shell deviations

-The primary seal operates independently and without interfering with the secondary seal.

-The seal can also be designed to suit internal floating roof decks.

Special models

- Customized seals are available.

– Seal for rivet tank.

– Teflon wiper seal.

– Low height secondary seal. – PE coated seal.

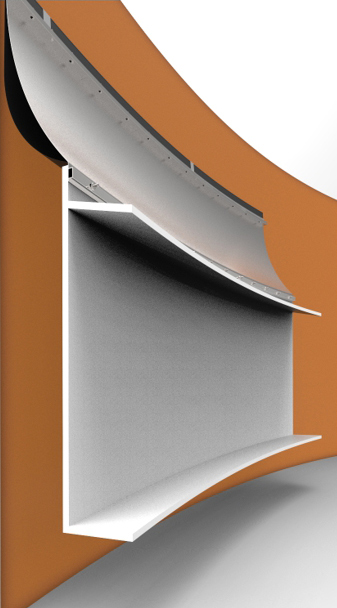

Various peripheral seal designs

WB-1

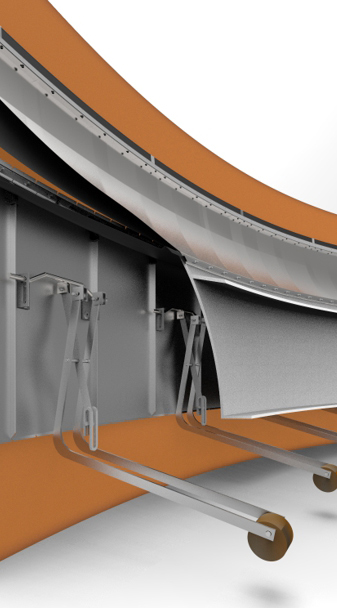

Pantograph Type Seal

- Rim space : 200mm ± 100mm

- Weight of seal: 45kg/m

- Widely used for crude oil Storage Tank

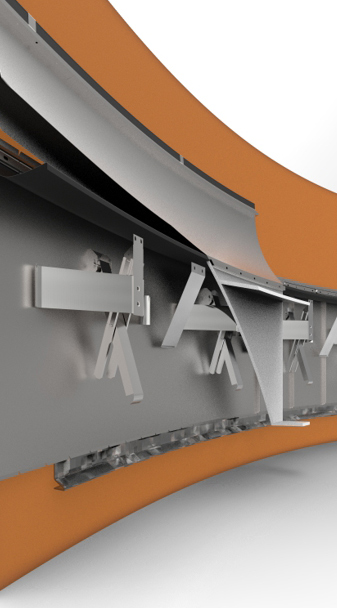

WB-2

Plate Spring Type Seal

- Rim space : 200mm ± 100mm

- Plate spring material: A240-301(Hard)

- Weight of seal:40kg/m

- Widely used for crude

WB-7

Graver Foam Type Seal

- Liquid & Vapor Mount ted type seal

- Envelope material: NBR, Teflon, PE

- Foam block material: PU

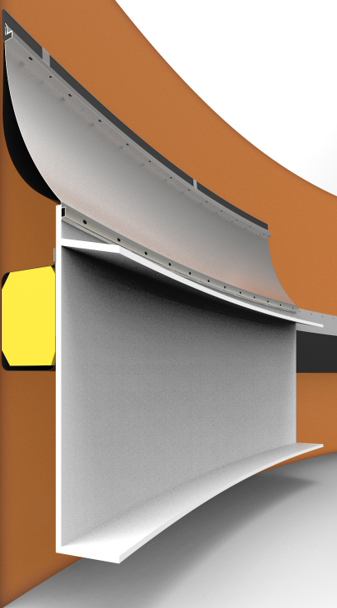

WB-50

Secondary Wiper Seal

- Wiper & Vapor barrier membrane for sealing

- Wiper Tip & Compression Plate for perfect weather shield