Water Treatment Plant Aluminum roof

Advantage of Aluminum Material

- Corrosion resistance

Aluminum reacts with oxygen in the atmosphere to form an oxide film on the surface.

– - Processability

Easy and excellent processability such as extrusion, roll pressing, forging, and precise cutting process.

– - Light weight

The specific gravity is 2.7 g/cm3, which is only 1/3 of carbon steel (7.8 g/cm3)

– - Recyclability

Low melting point of 659℃ (carbon steel 1530℃) – easy to regenerate and save energy, economical materials

– - Strength

1/3 weight of carbon steel but has the yield strength as much as carbon steel (245 MPa)

– - Non-Toxic

Sanitarily harmless, odorless, eco-friendly – food and medicine industry,

Key Benefts

| Economic feasibility |

|

| Maintenance |

|

| Durability |

|

| Heat reflectivity |

|

| Water plant industry |

|

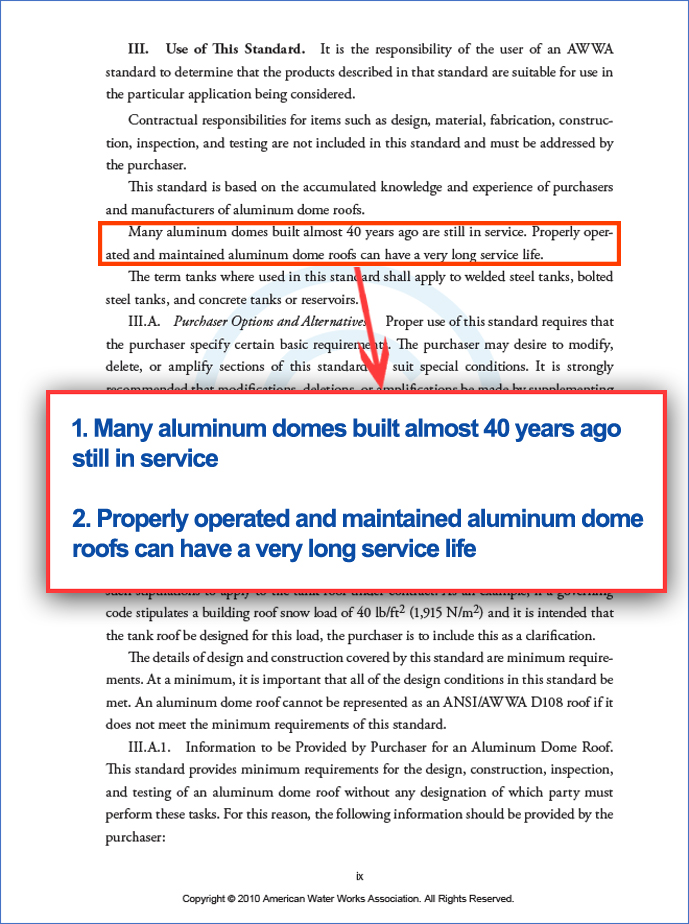

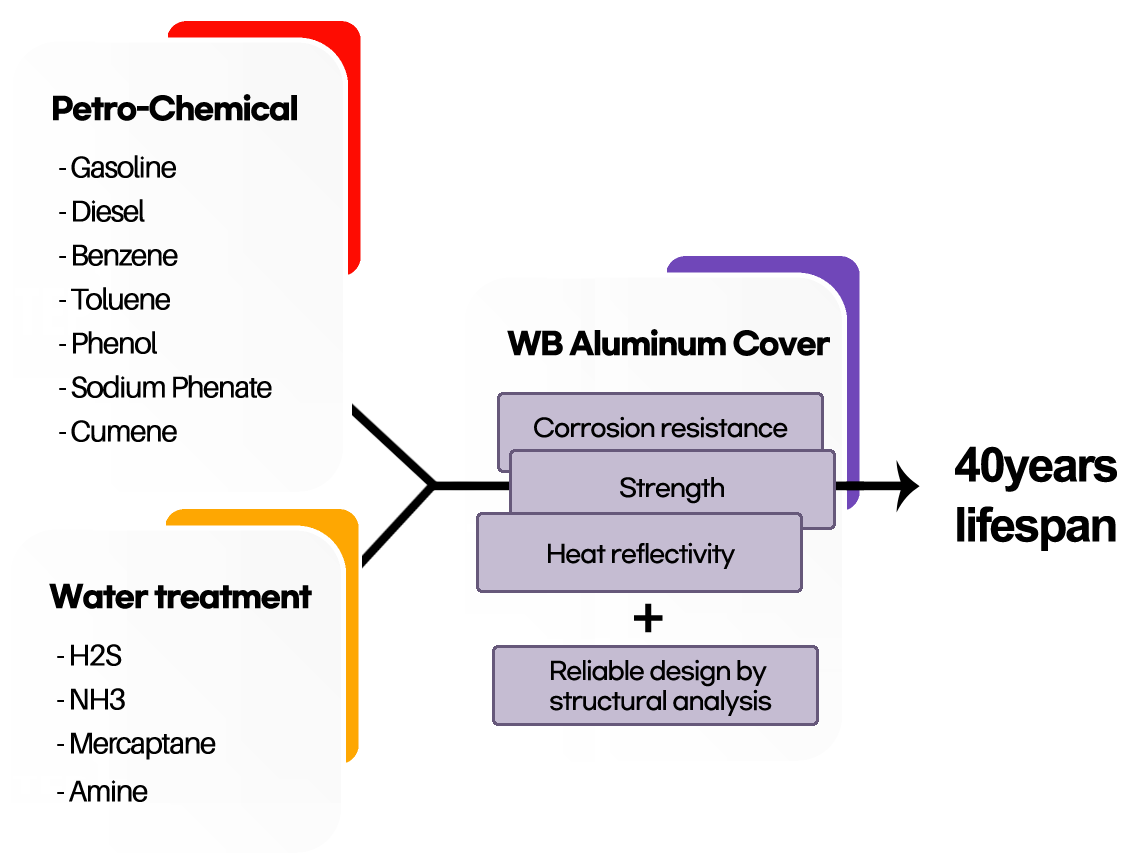

Expected Lifespan of Aluminum Covers

Reference – AWWA D108-10(first edition)

Aluminum Dome Roofs for Water Storage Facilities(Page 9)

Comparision table

| ITEM | Aluminum | SMC | Membrane |

| Material |

|

|

|

| Strength |

|

|

|

| Specific gravity | 2.7 | 1.6 – 2.0 | 1.0 – 1.5 |

| Lifespan | Longer than 40 years | 10-15years | 8-10years |

| Assembly time | Great | Normal | Normal |

| Corrosion resistance | Great | Bad | Bad |

| Air sealing | Great | Good | Good |

| Maintenance | Semi-permanent / almost no maintenance costs No maintenance required because there is no corrosion caused by UV or harmful gases |

Periodic coating for UV protection is required. Maintenance and maintenance costs are required due to discoloration, deformation, and cracks | Need to replace with short durability. Maintenance and maintenance costs are required due to discoloration, deformation, etc |

| Heat preservation | High thermal barrier properties (5% thermal transmittance, 95% reflectance) Minimize temperature change in the reservoir due to external temperature | Low thermal barrier Sensitive to the outside temperature, temperature changes in the reservoir are severe, and a separate device is required to maintain the temperature |

Low thermal barrier Sensitive to the outside temperature, temperature changes in the reservoir are severe, and a separate device is required to maintain the temperature |

| Simplicity | Assembly structure: Various types of structural geodesic dome and rectangular type can be manufactured and installed according to shape | Simple rectangular TYPE fabrication and installation only

|

When processing, it takes a long time to remove the adhesive part using a buffing machine and then perform high-frequency adhesion |

| Durability | Great | Good | Bad |

| Eco friendly |

|

General waste after end of lifespan | General waste after end of lifespan |

| Cost | 100 | 80-90 | 60-70 |